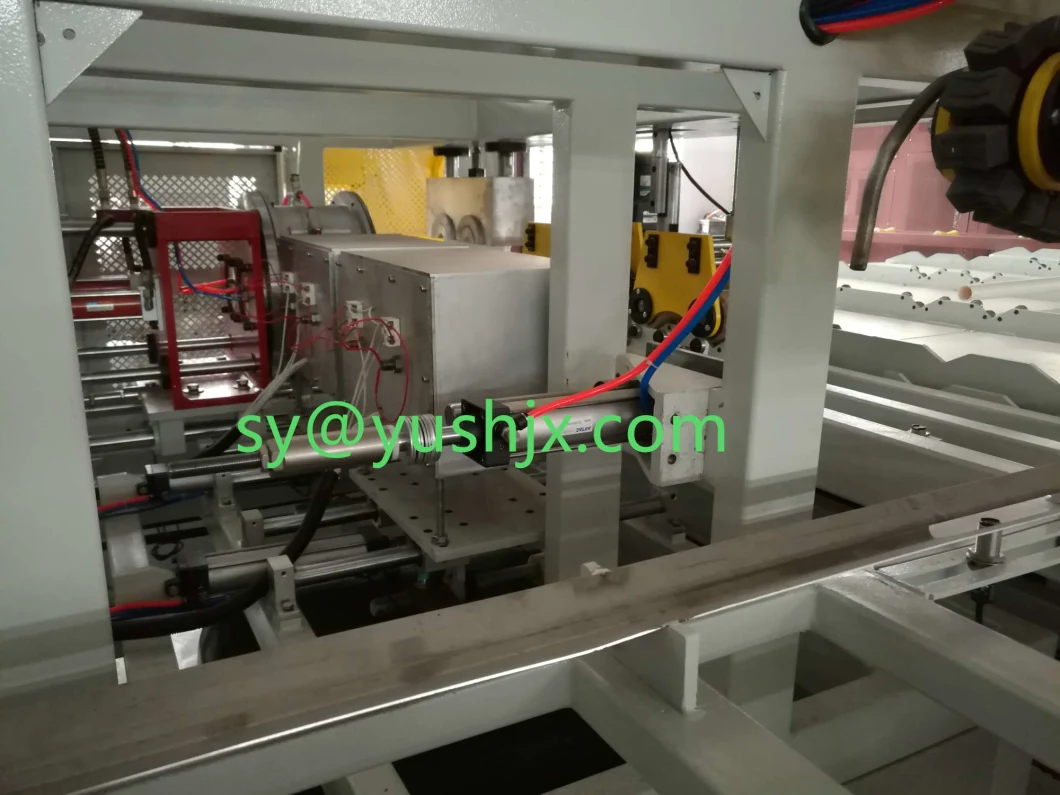

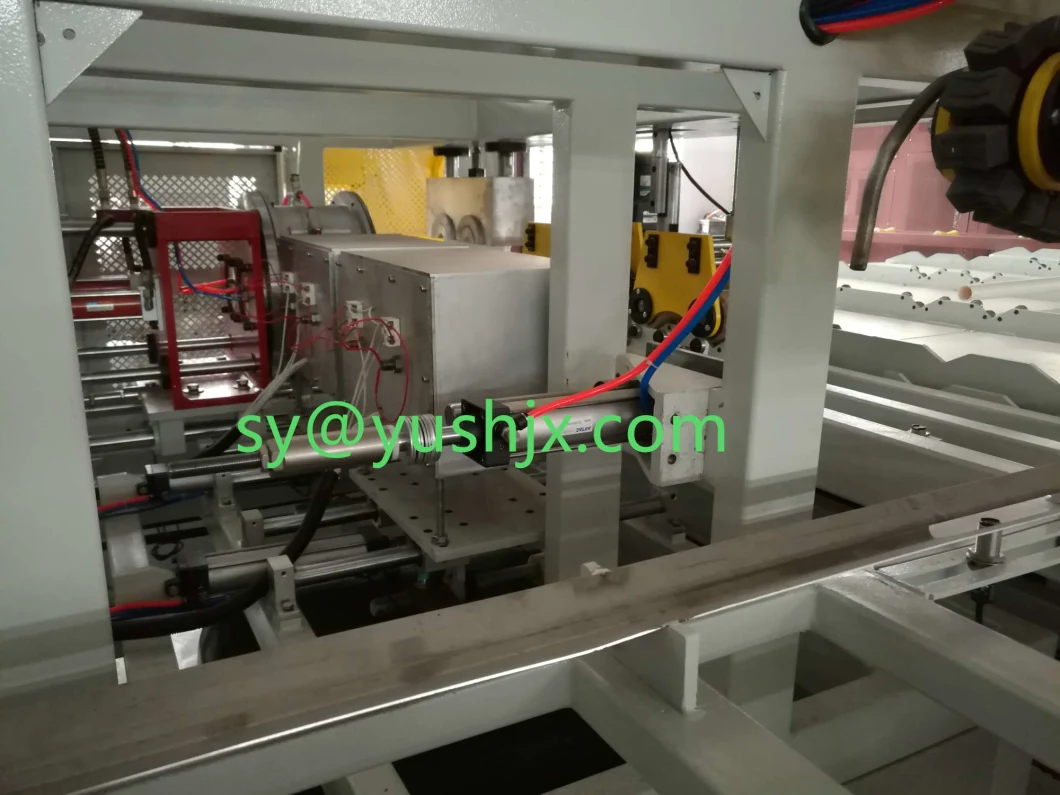

New Design Two Cavity PVC Pipe Extruding Machine/Belling Machine/Socket Machine

Features:

1-full automatic control by PLC

2-Online working

3-well known electric part: Siemens, Shneider, Omron, Autonics

4-Vacuum calibration

5-Water cooling

The pipe belling type: Straight type. The shaping method is mould expand. After shaping the air cooling of pipe are adopted to ensure precise belling size. The machine can be used on complete extrusion line with PLC control. The machine has the characteristic of advanced technique, easy operation and high automatic and so on.

Features:

1-full automatic control by PLC

2-Online working

3-well known electric part: Siemens, Shneider, Omron, Autonics

4-Vacuum calibration

5-Water cooling

The pipe belling type: Straight type. The shaping method is mould expand. After shaping the air cooling of pipe are adopted to ensure precise belling size. The machine can be used on complete extrusion line with PLC control. The machine has the characteristic of advanced technique, easy operation and high automatic and so on.

| Suitable for pipes | Pipe Size (OD) | 20mm-32mm |

| Pipe thickness | According to customer's request. Socket die tools will be made accordingly. | |

| Pipe length | 3-6m | |

| Socket end | Socket type | U type (solvent cement) |

| Socket length & socket sizes | According to customer's standard Have our own standards but molds can be made according to customer needs. | |

| Socket method | U type: push pipe onto die tools (with demould plate) | |

| Heating | Heating method | Stainless steel heating rods With hot air circulation inside the oven With pipe rotation |

| Heating oven | Two sets | |

| Heating power | 10kw | |

| Electrical Components | PLC, touch screen | Weinview |

| Temperature controller | RKC from Japan | |

| low-voltage apparatus | Schneider | |

| Sensors | Omron or Autonics | |

| Power | 380V 50HZ 3phase ( as requested) | |

| Total power | 14kw | |

| Cooling | Cooling method | water cooling |

| Cooling time | According to pipe size and thickness (adjustable on touch screen) |